PVTIME – In the ever-advancing photovoltaic (PV) sector, N-type cell technology has become a focal point. However, the UV sensitivity of HJT and TOPCon cells remains a major issue, degrading performance and shortening module life.

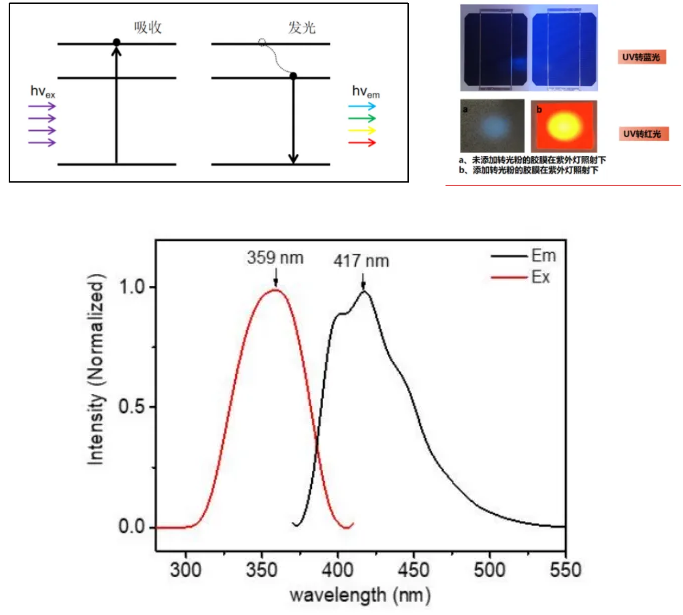

HIUV, an expert in thin film technology, has developed a game-changing UV light conversion film for solar cell packaging. Their proprietary UV conversion agent, a key component of this innovation, is synthesised through a complex chemical process. It begins with the selection of specific organic compounds that have high absorption capabilities in the UV spectrum. These compounds are then functionalised with reactive groups capable of forming covalent bonds with the matrix resin.

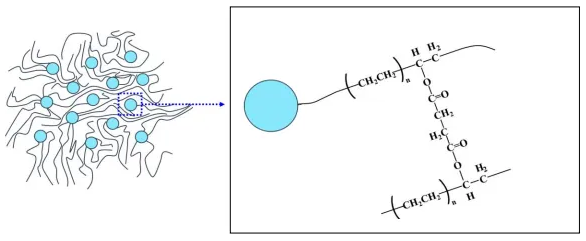

Once synthesised, this agent is cross-linked with a matrix resin. This cross-linking process takes place under precisely controlled temperature and pressure conditions in a special reactor. By adjusting reaction parameters such as reaction time, temperature (between 150-200°C) and pressure (around 5-10 atmospheres), HIUV engineers can optimise the formation of the robust macromolecular network. This network structure not only firmly anchors the UV converter within the film, but also provides a stable environment for the light conversion process. As a result, the film offers unrivalled resistance to migration and exudation, ensuring high conversion efficiency even under harsh conditions such as intense UV and high temperatures.

Tests show its superiority. While competitor films show 6-7mm of migration at 105°C over 96 hours, HIUV film shows zero migration. It achieves a quantum efficiency of almost 57% under a 240W/m² UV lamp. With an average transmittance of 17.69% in the 290-380nm range, it also remains stable under humid heat and UV aging conditions.

What makes HIUV different is its patented formulation. Unlike conventional conversion powders, the agent is chemically grafted onto the substrate resin during lamination. This is achieved by activating the reactive groups on the UV converter and the functional groups on the substrate resin using specific catalysts. The lamination process, whether for EVA or POE based encapsulants, involves heating the materials to a specific temperature (approximately 130 – 150°C for EVA and 140 – 160°C for POE) and applying pressure (approximately 1 – 3 atmospheres) to ensure a strong chemical bond is formed. This not only allows for a more stable and efficient light conversion process, but also provides legal protection against patent infringement.

HIUV film is a boon for PV module manufacturers, improving the economics of solar power systems by reducing costs and improving long-term efficiency. As the world moves towards decarbonisation, HIUV’s continued innovation in solar packaging positions the company to lead the way in making solar energy more accessible and sustainable. HIUV is currently in discussions with major manufacturers for exclusive supply and strategic partnerships in 2025.