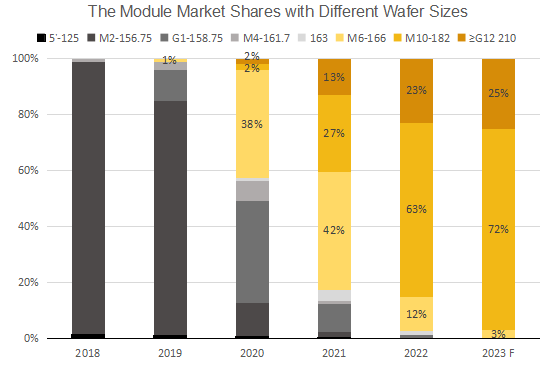

PVTIME – Following the recent release of the latest financial reports from major solar manufacturers, detailed sales information for all module types has become available. According to PV InfoLink, the large-format M10 module delivered over 196GW in 2022, accounting for 63% of the overall module market, with the G12 module shipping 70GW for a 23% share.

M10 had already established superiority over G12 during the period of p-type dominance and, as more n-type capacity is based on M10, its share will continue to increase in the coming years, all indications suggesting that, after years of debate, M10 has now positioned itself as the mainstream product.

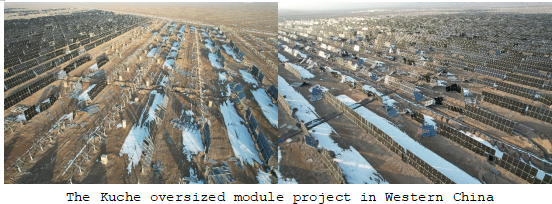

Since the launch of the M10 wafer size and module in 2020, orders and market share have continually increased due to an excellent balance of reliability and BOS savings. The number of plants suffering operational failures due to extreme weather has increased, particularly in the case of those deploying large G12 modules, as in the Kuche project in western China. The approach of offering super high power on a single module appears to be losing appeal as the industry discovers that efficiency is not improved in line with the increased surface area.

M10, in contrast, provides ease of handling, operational reliability and high performance in all plant scenarios.

As was witnessed last year, the capacity of high-efficiency cell technology is rapidly expanding. Nearly all newly built capacity is based on M10 dimensions, due largely to the fact that M10 offers a substantially higher manufacturing yield and cell efficiency. The coating quality on the wafer surface becomes increasingly difficult to manage as the wafer area grows larger, whereas most high-efficiency cells rely on high-quality coating layers to provide low contact resistance and effective passivation. Large wafers are also more prone to cracking throughout the manufacturing process.

In September 2021, the solar industry’s three largest manufacturers, JA Solar, Jinko Solar and LONGi, jointly issued a statement to the effect that the standard 72c format M10 module size of 2278×1134mm delivers a number of benefits to both the industry and its customers. The resultant adoption of a standardized module size introduced a level of certainty throughout the supply chain, enabling steady production without the need for frequent size changes. The standardization has also facilitated investment planning by providing a stable basis for system design. Customers now also have easy access to replacement modules of the same size, providing long-term operational benefits.

The universally adopted M10 module size has brought about consensus and achieved a market share of 72% over three years, the industry having learned from disputes over 157, 158 and 161mm module sizes in 2018.