PVTIME – With the continuous operation of large-scale utility power plants, the complementary power plant of grass and forest, which were once considered beneficial to ecological governance are facing new challenges. Against the backdrop of the expanding scale of photovoltaics, an influx of non-professional operation and maintenance personnel are entering the industry to contribute to its development. However, due to the lack of professional knowledge and experience, involved personnel of the power plant may engage in improper actions or use inappropriate tools, resulting in significant losses to the property of the PV power plant. Among these issues, the damage caused to PV module glass due to incorrect weeding methods in areas with high sand and stone content has emerged as a critical concern that cannot be overlooked. The following images and information will show the reason which caused damage of module glass, and it is necessary to draw attention from professionals within the photovoltaic industry.

(Images from left to right: Hand-held lawn mower in power plant, hand-held lawn mower)

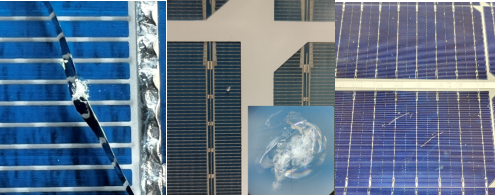

(Images from left to right: The visible damage to the naked eye, nearly imperceptible damage under normal observation)

A common instance of improper weed removal involves the utilization of a handheld lawnmower, which results in stone splashing on the ground and subsequently causing damage to nearby modules. This is particularly problematic in areas with exposed sand and stones, where even if there is no significant weed coverage, weeding operations are still necessary to prevent wild animals or meet regular operational and maintenance requirements. Although the hand-held lawn mower can effectively remove grass regardless of terrain limitations, the mowing rope at the front end tends to get entangled with the ground and propel sand and stones towards the photovoltaic module during sweeping. Based on investigations, it has been found that the hand-held lawn mower operates at an extremely high speed, with the rope’s end reaching speeds exceeding 100m/s. The splashing stones also move in a considerable velocity, resulting in significant impact forces that surpasses safety stress limits for the glass of bifacial module.

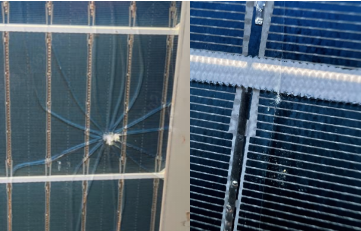

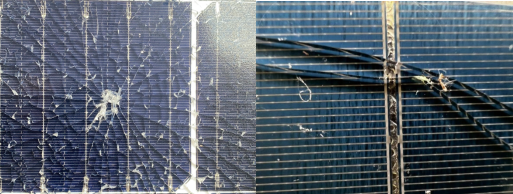

The impact of stone splashing on power plant modules can cause three types of damage: direct glass fracture, white impact points, and scratches. In the latter two cases, stress or vibration on the module may result in glass cracks, such as strong winds or twisting caused by the tracker system.

(Images from left to right: Tiny white impact point, white point under the magnifying glass, slight scratch)

According to a third-party investigation, the weeding operation that causes gravel splashing poses a risk of damaging the front glass of both bifacial and mono-facial modules. However, due to the installation angle, it has been observed that damage to the back glass occurs more frequently than damage to the front glass. This issue has also been replicated in laboratory tests for mono-facial modules with thicker glass (3.2mm). Therefore, effective measures must be implemented to prevent damage caused by flying stone impact on PV modules and ensure their safe operation.

(Images from left to right: mono-facial module damage and bifacial module back glass damage caused by hitting)

In the daily operation and maintenance of a photovoltaic power station, how can we prevent module damage caused by gravel splashing during weeding? Firstly, if the grass is not too high to be weeded, it is not recommended to weeding. If the lawn around the PV module is lower than the height which may affect normal module operation and maintenance, weeding should be avoided. Secondly, when performing weeding operations, It is advisable to use a sickle or professional weed equipment with a protective cover instead of a handheld lawnmower.

(Images from left to right: Anti-splashing automatic weeding robot, lawn mower)

Generally, the improper weeding practices can potentially result in stone splashes, leading to damage on PV modules. Seemingly inconspicuous behaviors during operation and maintenance processes may impact the stable functioning of the power plant. Only through adhering to scientific standards and implementing comprehensive and meticulous operation and maintenance management, as well as taking necessary preventive measures against unexpected situations, can we ensure the stable operation of the power plant while maximizing economic and environmental benefits from renewable resources.